How to Source Clothing from China — Practical Guide

This guide is a hands-on, start-to-finish playbook for international buyers (US / EU / UK / AU) who need to source clothing from China. You’ll get channel comparisons, sample & QC standards, a copy-ready RFQ, a worked landed-cost example, compliance notes for major markets, and a 10-point pre-production checklist you can use immediately.

Choose the channel that matches scale: 1688/Alibaba for price and speed; factory-direct for private label and control; trade shows for relationship building.

Always validate with a production sample + PSI; lab tests where safety/compliance matters (children’s wear, restricted substances).

Landed cost beats unit price — shipping, duty and broker fees commonly add 30–80% to a low FOB quote; calculate before ordering.

Labeling & documentation matter: country-of-origin, fiber content and care labels are enforced by customs/FTC/authorities. Non-compliance risks seizure and fines.

Why source clothes from China

Where to find suppliers (comparison table)

Sampling & quality control (standards & PSI)

How to contact & vet suppliers (templates & red flags)

Pricing & negotiation (cost drivers & terms)

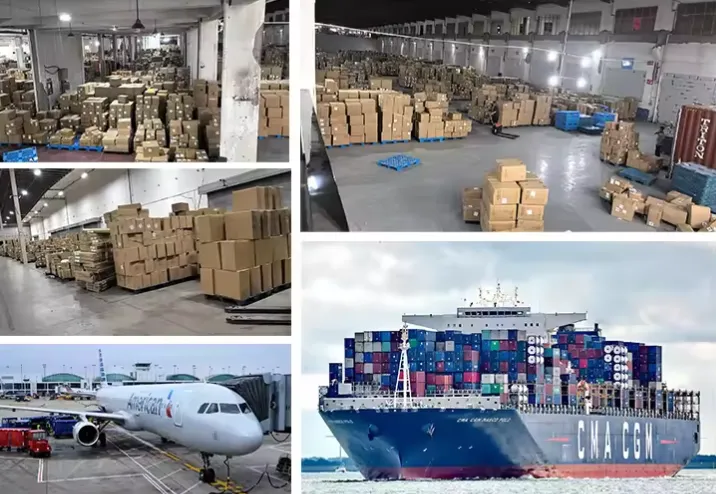

Logistics & shipping options (decision matrix)

Compliance & documents (US / EU/UK notes)

Risks & how to mitigate them

Practical templates (copy/paste)

Sample landed-cost worked example (step-by-step)

Before production — 10 things to check

FAQ + JSON-LD

China remains the world’s largest textile and garment exporter by volume, with dense clusters of specialized manufacturers that allow you to scale from small private-label runs to mass production. The major manufacturing clusters each have strengths: Guangdong (cut & sew, fast fashion), Zhejiang (knitwear, hosiery, Zhejiang/Yiwu for small orders), Fujian/Quanzhou (sportswear, footwear). Use cluster strengths when mapping a supplier search.

Strategic advantage summary:

Scale & variety — thousands of suppliers across product types.

Speed to market — local sourcing agents, trade shows and market hubs allow fast sampling and negotiation.

Competitive pricing — especially for basic garments; margins depend on design complexity and material specs.

Pick the right channel for your objective — speed, price or control. Below is a compact comparison you can use to choose a first approach.

| Channel | Typical MOQ | Lead time (sample → production) | Best for | Risk |

|---|---|---|---|---|

| Alibaba (intl listings) | 300–1,000 | 2–6 wks | Middle-tier OEM; easy contact | Mixed vetting; trading companies listed |

| 1688 (China domestic) | 50–500 | 1–4 wks | Lowest price, small MOQ (need Chinese agent) | Language + export capability |

| Made-in-China / Global Sources | 200–1,000 | 2–6 wks | Factory/direct; trade show tie-ins | Variable verification |

| Trade shows (Canton, Yiwu) | Negotiable | Meetings → 4–12 wks | Build relationships, audit on-site | Travel cost; seasonal timing. |

| Factory-direct (via agent) | 500+ | 4–12 wks | Private label & strict QC | Requires strong due diligence |

| Sourcing agent / trading co. | 200+ | Varies | Speed + local handling | Extra margin; less direct control |

Under 500 pcs: we source via 1688 through our China agent to save cost; for strict spec/IP control we handle factory-direct sourcing and arrange audits + PSI. Contact us.

Showroom sample: representative, may not use your exact fabric/print. Not acceptable as approval.

Production sample: made from your tech pack, your fabric, trims, labels and packaging — this is the approval.

Send a sample specification sheet: fabric SKU, GSM, color codes (Pantone), trims, size spec.

Ask for photos of raw fabric roll numbers (to trace dye lot).

Request production photos of sewing lines and an estimated BOM with trim sources.

For safety-sensitive items (kids, flame retardant, restricted chemical content), order independent lab tests before bulk ship.

Book a pre-shipment inspection (PSI) with a recognized provider (SGS, Bureau Veritas, Intertek). PSI usually samples using AQL/ISO 2859-1; acceptance criteria and sample sizes must appear in the PO.

| Item | Target / Tolerance |

|---|---|

| Fabric color match | Delta ≤ 2 ΔE or buyer acceptance |

| GSM | ±3% |

| Stitch per inch | As specified in tech pack |

| Seams & strength | No skipped stitches; seam strength test pass |

| Dimension | ±1 cm tolerance per size spec |

| Print/embroidery placement | ±5 mm position tolerance |

| Packaging & labels | Count per carton confirmed; sample photo of carton |

Make these numeric tolerances contractual items in your PO.

Factory or trading company? — request a copy of the business license and export license.

Annual export volumes for your SKU — capacity check.

Sample lead time and costs.

Minimum order quantity (MOQ) by SKU and by color.

Payment terms & bank details (confirm bank account name).

Third-party inspection acceptance.

Certifications (OEKO-TEX, GOTS, ISO) if needed.

Reference customers — request references and recent order pictures.

Intellectual property protection — willingness to sign NDA/IP clause.

Trims supply — are trims sourced locally or imported (affects lead time)?

Inability or refusal to provide factory photos or license.

Price dramatically below market with push to pay full up front.

Multiple bank accounts or frequent bank changes.

Fabric — typically largest cost line (fiber type, yarn count, finishing).

Trims — zips, buttons, labels, hangtags.

Labor / cut & sew complexity — price jumps with added operations (lining, padding, quilting).

Packaging / folding / polybags.

30% deposit / 70% before shipment (T/T) — common for new suppliers.

L/C (Letter of Credit) — for large orders, reduces seller risk but adds bank cost.

Escrow / Trade Assurance (Alibaba) — secure for middle ranges.

Increase MOQ to lower unit price.

Bundle SKUs to achieve scale discounts.

Commit to rolling orders for improved terms.

Adjust lead time — longer lead times can unlock lower labor premium.

Express (DHL/UPS/FedEx) — samples and <200 kg high-value parts. Fast but expensive.

Air freight (air cargo) — urgent replenishment; calculate per-kg rates and volumetric weight.

Sea freight — LCL — small cartons consolidated; good for small bulk where FCL not filled.

Sea freight — FCL — best for volume (500+ cartons typical).

Sea + truck — hybrid options for regional hubs; sometimes cheaper/time-balanced.

Sea FCL (China port → US east coast) typical door-to-door 35–50 days depending on route and drayage. Air 3–10 days. Use your forwarder to estimate carrier cutoffs and season peaks.

Use a landed-cost provider (Zonos, DutyCalculator) or your freight forwarder. These services calculate duty, VAT, and local fees based on HS code and country. Always confirm using the correct HS code for textile items.

Commercial Invoice (itemized)

Packing List (carton counts, gross/net weights)

Bill of Lading / Air Waybill

Certificate of Origin (if preferential duty or buyer requires)

Test reports / safety certificates (when applicable)

United States: FTC and CBP enforce labeling and country-of-origin rules (fiber content, care labels). Verify labeling requirements before shipment.

EU / UK: importers need EORI registration; VAT and duty depend on HS classification and origin. Post-Brexit, UK import processes include specific documentation and possible additional checks.

Non-delivery / fraud: mitigate with small first orders, trade assurance or escrow, and verified references.

IP leakage: register trademarks in target markets; use NDAs and specific IP clauses in contracts.

Quality drift: require production samples, in-line photos at milestones, and PSI on final lots.

Regulatory change: monitor customs/FTAs; duties and de-minimis can shift quickly — subscribe to customs updates.

Assumptions (example): FOB unit $3.50; quantity 500; sample $60; sea freight (LCL) $400; insurance $20; broker $100; customs clearance fee $50; duty 12% on CIF.

Step-by-step (numbers verified):

Product cost = 500 × $3.50 = $1,750.00.

Shipping + insurance = $400 + $20 = $420.00.

CIF value = $1,750.00 + $420.00 = $2,170.00.

Duty (12%) = $2,170.00 × 0.12 = $260.40.

Other fees = $100 + $50 = $150.00.

Total landed = $2,170.00 + $260.40 + $150.00 = $2,580.40.

Landed cost per unit = $2,580.40 ÷ 500 = $5.16.

This shows a $3.50 FOB tee can land at ≈ $5.16 once shipping, duty and fees are included. Use actual HS code & forwarder quotes to replace the assumptions.

Approved production sample signed and dated.

Final tech pack with measurements & tolerances.

Confirmed BOM (fabric, trims with supplier SKUs).

MOQ, unit price and payment schedule in PO.

PSI company and sample size confirmed.

Shipping method and estimated lead time confirmed.

HS code & estimated duty confirmed with forwarder.

Packaging spec and barcode/SKU labels ready.

Insurance coverage agreed.

Signed order confirmation with penalty & remedy clauses.

Q1: Can I source from 1688 without speaking Chinese?

A1: Yes — via a Chinese-speaking agent or a forwarder; 1688 often has lower prices but requires domestic payment and export handling.

Q2: Should I always run a PSI?

A2: For bulk orders yes — PSI catches quantity and quality deviations; for low-value small orders you might rely on sampling and photo checkpoints.

Q3: How do I calculate duty?

A3: Duty is applied to the customs value (often CIF) and depends on HS code. Use a landed cost tool or your customs broker for precise calculation.

Q4: Is an L/C better than T/T?

A4: L/C reduces seller risk and is safer for large orders; T/T is cheaper and faster for trusted suppliers.

Q5: What is the typical lead time for knitwear?

A5: Samples 1–3 weeks; production 4–10 weeks depending on complexity and capacity.

Q6: Do I need to register to import?

A6: For commercial imports yes — importers usually need local business registration and tax/VAT registration (EORI in EU/UK).

Q7:How should I structure a returns & defects policy with a Chinese supplier?

A7 — Put clear acceptance windows, an agreed defect threshold (e.g., % by lot), remedies (repair, replacement, or refund), who covers return shipping, and a dispute resolution clause (jurisdiction/arbitration). Record it in the PO and link to photos/measurement evidence as the reference standard.

Q8 :What’s the fastest way to check a factory’s social and environmental compliance?

A8 — Ask for recent audit certificates (SMETA, BSCI, ISO) and the auditor’s report, verify certificate numbers with the issuing body, and request timestamped factory photos or short video of production lines and dormitories — then hire a short remote audit or local third-party if anything looks off.

Q9:After a successful small run, how do I ramp up without losing quality?

A9— Lock the BOM and approved suppliers, require the same fabric lot numbers or equivalent mill reports, do staged increases (e.g., 25% → 50% → full run) with checkpoints at each ramp stage, and include an early-order quality audit and acceptance sign-off before full payment.

Q10:How can I reduce color variation between dye lots across multiple orders?

A10 — Require lab dip approvals with spectral Delta-E tolerances, record dye lot numbers on the tech pack, and contractually require fabric to be cut from the same dye lot or provide an approved shade band for acceptable variance.

Q11:How should I prepare packaging so garments are retail-ready across channels?

A11 — Define channel-specific packaging in the spec: barcode type (EAN/UPC/GS1), folding method, polybag dimensions and material, hanger/ticket placement, inner carton labeling (SKU, qty, net/gross wt), and any retailer prep (polybagging, polybag perforation, or FBA stickering).

Q12: How do I verify a mill’s claim that fabric is “organic” or “sustainable”?

A12 — Request original certificates (GOTS, OEKO-TEX, GRS) with mill name and batch numbers, ask for chain-of-custody/mass-balance documentation, cross-check certificate validity on the certifier’s site, and, for high-risk buys, arrange third-party material verification tests.

Contact us

Call Us: +86 193 7668 8822

Email:[email protected]

Add: Building B, No.2, He Er Er Road, Dawangshan Community, Shajing Street, Bao'an District, Shenzhen, China