Sourcing Metal from China: The Importer's Guide to Cost, Quality & Logistics

Sourcing metal products—from simple fasteners to complex custom fabrications—from China offers significant advantages in cost and manufacturing capability. However, the path is fraught with potential pitfalls: inconsistent quality, communication gaps, hidden costs, and complex logistics.

This guide isn't just another generic overview. It’s a detailed, step-by-step playbook written from the perspective of logistics experts who see what makes metal importers succeed or fail. We will walk you through the entire process, with a sharp focus on the specifics of metal sourcing, to ensure you import with confidence.

Use the links below to navigate this comprehensive guide:

Before You Start: Define Your Sourcing Parameters

Step 1: Finding and Vetting Reliable Metal Suppliers

Step 2: Communication and The Art of the RFQ

Step 3: Decoding Quotes and Incoterms for Metal

Step 4: Sampling and Metal-Specific Quality Control

Step 5: Contract Negotiation and Payment Terms

Step 6: Logistics Planning for Metal Products (Sea, Air, Rail)

Step 7: Production Monitoring, Shipping, and Customs

Deep Dive: Calculating the True Landed Cost of Metal Parts

FAQ: Sourcing Metal from China

Rushing to contact suppliers without a plan is the most common mistake. Answer these four questions first to build a solid foundation.

Product Specifications: Be precise. It's not just "steel brackets." It's "Q235 Steel Brackets, 5mm thickness, with zinc plating (ZY3), tolerance ±0.2mm." Create a technical data sheet with drawings. Ambiguity invites quality issues.

Order Volume: Are you ordering samples, a pilot run (500 units), or full-scale production (10,000+ units)? This directly impacts your pricing and which suppliers will work with you. Understand Minimum Order Quantities (MOQs).

Budget & Timeline: What is your target Cost, Insurance, and Freight (CIF) or Landed Cost per unit? How critical is your deadline? Realistic timelines prevent costly air freight surprises.

Compliance Requirements: What certifications are mandatory for your market? Common ones include ISO 9001 for quality management and RoHS for restricted substances. For structural metals, you may need a Mill Test Certificate (MTC) verifying the material's chemical and physical properties.

Finding suppliers is easy; finding reliable ones is the challenge.

Where to Look:

B2B Platforms: Alibaba, Made-in-China.com, and Global Sources. Use specific keywords like "CNC machined aluminum parts" or "stainless steel fabrication."

Industry Directories: For more specialized manufacturers, consider industry-specific directories or trade associations.

How to Find a China Sourcing Agent: A good agent on the ground has pre-vetted networks and can conduct factory audits.

Vetting for Credibility How to Find Trustworthy Suppliers in China (Go Beyond the Profile):

Business License: Request a copy to verify legitimacy.

Factory Audit Reports: Ask for reports like an Alibaba Verified Report or, even better, a third-party audit (e.g., SGS, BV). Look for evidence of quality control processes.

Production Equipment: Ask for photos or videos of their workshop. A factory with modern CNC machines and laser cutters is a better bet for precision parts than one with basic manual equipment.

Client References: Ask for examples of similar metal products they've manufactured for other international clients.

Crafting a Professional RFQ: A Template You Can Use

Your initial inquiry sets the tone. A professional RFQ signals that you are a serious buyer. Below is a template tailored for metal parts. Copy, paste, and customize it.

Email Subject: RFQ: [Quantity] of [Product Name/Description] - [Your Company Name]

Email Body:

Dear [Supplier Contact Name],

My name is [Your Name] from [Your Company]. We are a [describe your business, e.g., manufacturer of industrial equipment] based in [Your Country].

We are seeking a long-term manufacturing partner for a new component and are interested in your capabilities for producing the following:

Product: [e.g., Precision Stamped Steel Bracket]

Material: [e.g., Cold Rolled Steel, Q235, 2.0mm thickness]

Finish: [e.g., Zinc Plating, Blue Trivalent]

Quantity: Initial order of [e.g., 10,000] pieces, with projected annual usage of [e.g., 100,000] pieces.

Please find attached:

Detailed Technical Drawing (PDF)

Specification Sheet

We request a quotation based on the following:

Incoterm: FOB Shanghai

Pricing for both the initial and annual quantities.

Sample cost and lead time.

Production lead time for the initial order.

Please confirm your experience with exporting to [e.g., North America] and any relevant quality certifications (e.g., ISO 9001).

We look forward to your reply.

Best regards,

[Your Name]

[Your Title]

[Your Company]

[Your Phone Number]

Your Request for Quotation (RFQ) sets the tone. A professional RFQ gets you a serious quote.

Your RFQ should include:

A clear subject line: "RFQ for 5,000 pcs of 304 Stainless Steel Flanges - [Your Company Name]"

A brief introduction to your company.

Detailed technical drawings/specifications (attach PDFs).

Material grade and finish requirements.

Desired quantity and target price (if known).

Preferred Incoterm (we'll cover this next).

Request for a sample cost and lead time.

Pro Tip: Avoid only discussing price. Ask technical questions about their manufacturing process for your part. Their answers will reveal their expertise.

When quotes arrive, understanding the details is crucial.

Price Breakdown: Ensure the quote itemizes the unit price, tooling/mold cost (if any), and packaging cost.

Incoterms 2020 - Critical for Logistics:

EXW (Ex Works): You pay for everything from the factory gate onward. You have full control but also full responsibility. Best for experienced importers with a trusted freight forwarder in China.

FOB (Free On Board): The supplier gets the goods to the port and loaded on the ship. You pay for the main ocean freight, insurance, and destination costs. This is the most common and often recommended term as it clearly divides responsibility.

CIF (Cost, Insurance, and Freight): The supplier arranges and pays for the shipment to your destination port. This seems easier, but you lose control over carrier selection and freight costs. The supplier may not arrange adequate insurance.

For most importers, FOB is the safest choice, allowing your freight forwarder to handle the main logistics leg.

Never skip the sampling stage.

The Sample Process: Pay for production samples (not just off-the-shelf catalog items). Insist they are made from the correct material with the specified finish.

Metal Product QC Checklist:

A generic checklist isn't enough. Your inspection must be metal-specific.

Dimensions & Tolerances: Use calipers, micrometers, and CMMs for critical dimensions. Check against your drawing.

Material Verification: Confirm the material grade. This can be checked visually (material markings) or via a spectrometer for exact chemical composition. Request the Mill Test Certificate.

Surface Finish: Check for consistency in plating, painting, or anodizing. Look for scratches, discoloration, or uneven coating.

Workmanship: Check for burrs, sharp edges, warping, or visible weld seams that shouldn't be there.

Packaging: Is the packaging robust enough to prevent rust (using VCI paper) and damage during a long sea voyage?

A generic checklist won't suffice for metal parts. Your inspection needs to be precise and technical.

1. Decoding the Mill Test Certificate (MTC)

The MTC is your guarantee of material quality. Don't just file it away; understand it. Here’s what to look for:

Grade Confirmation: Verify the material grade (e.g., SS304, Q235) matches your order.

Chemical Composition: Check that key element percentages (like Chromium and Nickel in stainless steel) fall within the standard's range.

Mechanical Properties: Confirm yield strength and tensile strength meet the required specifications.

2. Essential Measurement Tools

Calipers: For general dimensional checks (length, width, hole diameters).

Micrometers: For highly precise measurements, especially material thickness.

CMM (Coordinate Measuring Machine): For complex geometries and verifying positional tolerances on critical components.

3. Common Metal Defects to Identify

Train your eye to spot:

Surface Imperfections: Scratches, discoloration, inconsistent plating/anodizing.

Workmanship Issues: Burrs (sharp edges), warping, splattered weld residue.

Corrosion: Signs of rust, especially if improper packaging was used.

A clear contract protects both parties.

Key Clauses What to Require from a Sourcing Agent in China:

Product Specifications: Attach the final approved drawings and sample photos.

Quality Standards & Acceptance Criteria: Define the AQL (Acceptable Quality Level) for inspections.

Delivery Date: Specify the date and include penalties for delays.

Payment Terms: Typical terms are 30% deposit with order, 70% balance against copy of Bill of Lading. This balances risk for both sides.

Intellectual Property (IP): Ensure the contract states that your designs are your IP.

Making the Right Shipping Choice: It's About Your Priorities

Understanding the theory behind each shipping method is one thing. Making the right choice for your specific metal order is another. The table below provides a clear comparison, but the real key is matching the method to your business needs.

| Shipping Method | Best For... (Real-World Scenarios) | Typical Transit Time | Cost | Key Considerations for Metal |

|---|---|---|---|---|

| Sea Freight | High-volume, non-urgent orders. You've filled a 40ft container with steel structures, and your sales season is 8 weeks away. Cost-efficiency is your primary driver. | 30-45 days | Lowest cost per kg | Ensure packaging is robust and moisture-resistant (VCI paper) to prevent rust during the long voyage. |

| Air Freight | Speed is critical. A batch of 200kg of precision copper components is needed to restart a production line losing $500 per minute. The premium for speed is justified. | 3-7 days | Highest cost per kg | Cost is calculated on chargeable weight (actual vs. volumetric). Ideal for high-value, low-weight items. |

| Rail Freight | Balancing cost and time for land-based routes. You have 15 tons of stainless steel kitchenware destined for an inland European city. It needs to be faster than sea, but your budget can't stretch to air. | 18-22 days | Moderate | A reliable option on key routes like China-Europe, often less affected by port congestion than sea freight. |

Your Decision Flow:

Still unsure? Ask yourself these questions:

What is the total weight/volume? (If over 500kg or 2CBM, air freight becomes less economical).

How time-sensitive is the shipment? (Is it a stop-gap emergency or planned inventory restock?).

What is your top priority: Lowest Cost, Predictable Speed, or Absolute Fastest?

This framework moves beyond simple comparison and helps you align your logistics strategy with your business objectives.

This is where expertise matters most. Metal products are often dense and heavy, making logistics choices critical.

| Shipping Method | Best For | Typical Transit Time | Cost | Key Considerations for Metal |

|---|---|---|---|---|

| Sea Freight | High-volume, heavy orders. (Full containers of steel structures, large batches of parts). | 30-45 days (e.g., China to EU/US) | Lowest cost per kg | Ideal for most metal sourcing. Ensure proper packaging and crating to prevent moisture damage and rust. |

| Air Freight | Urgent, low-volume, high-value orders. (Prototypes, small batches of precision parts). | 3-7 days | Highest cost per kg | Speed comes at a premium. Calculate based on chargeable weight (actual vs. volumetric). |

| Rail Freight | Land-based routes (China to Europe). Balanced speed and cost. | 18-22 days | Moderate, between sea and air | Growing in popularity for its reliability. Good for time-sensitive bulk orders not urgent enough for air. |

Your freight forwarder will handle:

Booking: Securing space with the carrier.

Customs Clearance (Export): Preparing documentation for Chinese customs.

Cargo Insurance: Highly recommended to cover loss or damage during transit.

Tracking: Providing you with real-time updates.

Production Follow-up: Maintain regular contact with the supplier. Request periodic photos or videos of the production process.

Pre-Shipment Inspection: For large orders, hire a third-party inspector to check the goods at the factory before they are packed.

Customs Clearance at Destination: This is your responsibility. Your freight forwarder at the destination port can handle this as your agent. You will need to provide:

Commercial Invoice

Packing List

Bill of Lading

Certificate of Origin

Any other required permits (e.g., for certain steel products, import licenses may be needed).

The unit price from the supplier is just the beginning. The Landed Cost is what you actually pay to have the goods at your door.

Example: Sourcing 10,000 kg of Machined Steel Components (FOB Shanghai)

| Cost Factor | Calculation | Estimated Cost (USD) |

|---|---|---|

| Product Cost | 10,000 kg * $3.50/kg | $35,000 |

| Tooling/Mold Cost | One-time cost | $1,500 |

| Packaging | Wooden crates & pallets | $800 |

| Supplier Total (FOB) | $37,300 | |

| Ocean Freight | Shanghai to LA: $2,500 (for a 20' container) | $2,500 |

| Marine Insurance | 0.3% of goods value | ~$112 |

| Customs Duties | e.g., 4.5% on steel products | $1,678.50 |

| Port & Handling Fees | THC, Documentation, etc. | $600 |

| Inland Trucking | From LA port to your warehouse | $400 |

| Importer Total | $5,290.50 | |

| Total Landed Cost | $42,590.50 |

Cost per kg = $42,590.50 / 10,000 kg = $4.26/kg (Not the original $3.50!)

This exercise is vital for accurate pricing and profitability analysis.

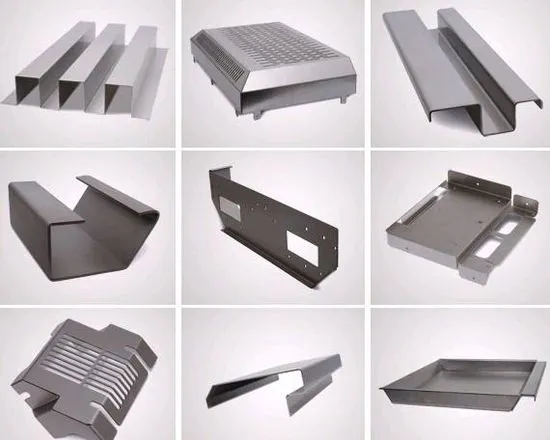

Let's move from theory to practice. Here’s a realistic cost breakdown for sourcing a batch of custom sheet metal enclosures. This is what you need to budget for.

Scenario: Sourcing 1,000 units of a fabricated sheet metal enclosure.

Sample Unit Price (5 pcs): $50/unit (high due to setup)

Sample Tooling/NRE (Non-Recurring Engineering): $300

Express Courier (DHL/FedEx to your door): $150

Total Sample Cost: (5 * $50) + $300 + $150 = $700

This is the cost to have the goods at your warehouse.

| Cost Factor | Calculation | Cost (USD) |

|---|---|---|

| Product Cost | 1,000 units @ $15/unit (bulk price) | $15,000 |

| Production Tooling | Amortized for this order | $2,000 |

| Export Packaging | Custom cartons & edge protectors | $500 |

| Subtotal (FOB Value) | $17,500 | |

| Ocean Freight | Shanghai to Hamburg (20ft Container) | $1,800 |

| Marine Insurance | 0.3% of FOB Value ($17,500) | $52.50 |

| Destination Port Fees | Handling, documentation, etc. | $400 |

| Import Duty | Assume 4.5% on FOB Value | $787.50 |

| Inland Trucking | Port to Warehouse | $250 |

| Total Landed Cost | $20,790 |

The Real Cost Per Unit: $20,790 / 1,000 units = $20.79

Notice how the initial $15 unit price becomes $20.79 once all costs are included. This detailed breakdown is essential for accurate pricing and profitability analysis. Never base your decisions on the supplier's unit price alone.

1. Q: I have a design for a custom metal part, but no technical drawings. Can Chinese manufacturers work with just a 3D CAD file?

A: Yes, most modern manufacturers prefer 3D CAD files (like STEP or IGS formats) as they can directly program their CNC machines from them. However, for complex parts, it's highly recommended to also provide a 2D PDF drawing with critical dimensions, tolerances, and surface finish notes. This eliminates ambiguity and serves as the definitive reference for quality inspection.

2. Q: What's the best way to handle a situation where my supplier is consistently missing production deadlines?

A: First, communicate directly but professionally to understand the reason (material delay, labor shortage, etc.). Refer to your contract's penalty clause for delays, if one exists. Simultaneously, activate your backup plan by contacting alternative suppliers you may have vetted initially. To prevent this, always build a buffer into your planned timeline and consider using a production tracking service for regular updates.

3. Q: Are there any metal products that are particularly difficult or restricted to export from China?

A: Generally, finished goods are straightforward. However, exports of certain scrap metals or primary raw materials (like certain rare earth metals) can be restricted or subject to high export duties. For finished products like steel, some countries may have anti-dumping duties, which is an import issue at your end, not an export issue from China.

4. Q: My metal parts arrived with minor surface rust. What should I do and who is responsible?

A: This is often a packaging issue. Basic packaging may not have included anti-rust (VCI) paper or was damaged during transit. Responsibility can be complex: was the packaging specified in your contract? Was the shipping insurance claimed for water damage? Immediately document the issue with photos. For minor rust, it may be more cost-effective to clean it locally and negotiate a partial refund or credit from the supplier for the next order, insisting on proper anti-rust packaging in the future.

5. Q: How do I calculate the volumetric weight for my metal products if I need to ship by air?

A: Air freight charges are based on volumetric weight (the space it occupies) if it's greater than the actual weight. The formula is: (Length x Width x Height in cm) / 6000 = Volumetric Weight in kg. Compare this to the actual weight. For dense metal items, you'll often pay by actual weight. But if your goods are lightweight but bulky (e.g., large wire mesh panels), you could pay by volumetric weight.

6. Q: What is a "Golden Sample" and why is it critical for metal sourcing?

A: A "Golden Sample" is the final approved sample that you and the supplier both sign off on before mass production. It is sealed and stored as a physical reference. This sample definitively sets the standard for quality, finish, and workmanship. If a dispute arises later about whether the production batch matches the quality, the Golden Sample is the objective arbiter.

7. Q: Is it possible to source small quantities of metal products from China, or do all factories have high MOQs?

A: It is possible, but you need to target the right type of supplier. Large factories have high Minimum Order Quantities (MOQs). Look for smaller workshops or "trading companies" that aggregate orders. Be prepared to pay a significantly higher unit price for small batches to cover the factory's setup costs. Your best strategy is to be transparent about your low volume but emphasize potential for future growth.

8. Q: Besides Alibaba, are there other platforms to find specialized metal manufacturers China Textile Sourcing?

A: Yes. While Alibaba is broad, consider more industry-specific B2B platforms like Global Sources (often higher-quality suppliers) or MFG.com (for custom mechanical parts and sourcing requests). For certain industries, attending trade shows like China's Canton Fair (both online and physical editions) remains an excellent way to connect with vetted manufacturers.

9. Q: What are the key cultural tips for effective communication with my Chinese metal supplier?

A: Building rapport is key. Be direct but always polite. Avoid confrontational language. Understand that "yes" might mean "I understand" not necessarily "I agree." During negotiations, be patient and avoid ultimatums. Using a messaging app like WeChat can foster a more direct and responsive communication channel after the initial formal contact.

10. Q: When is it worth hiring a third-party inspection The Ultimate Guide to Sourcing and Importing Essential Oils from China company in China, and what do they actually do?

A: It's highly recommended for your first large order or when the value is significant. Inspectors do more than just check products. They conduct a pre-shipment inspection at the factory, which includes verifying quantity, checking a statistical sample against your specifications (dimensions, function, appearance), and assessing packaging. They provide a detailed report with photos and data, giving you an objective view of quality before you pay the balance.

Contact us

Call Us: +86 193 7668 8822

Email:[email protected]

Add: Building B, No.2, He Er Er Road, Dawangshan Community, Shajing Street, Bao'an District, Shenzhen, China