What Are the 5 P's of Purchasing? A Procurement Professional's Guide

If you've searched for "the 5 P's of purchasing" online, you've probably found yourself more confused than when you started. Most articles either talk about marketing's 4 P's or discuss the "5 Rights" of procurement instead.

Here's the truth: the 5 P's framework in purchasing is fundamentally different from marketing, and when properly understood, it becomes one of the most powerful tools in your procurement toolkit.

Let's clear up the confusion once and for all.

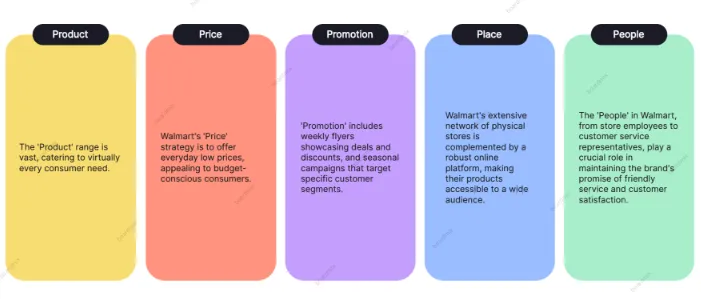

Marketing's classic 4 P's (Product, Price, Place, Promotion) focus on selling. But in procurement, we're focused on buying strategically. That's why we've adapted the framework with a crucial fifth P: Process.

Think of it this way: while marketing tries to influence buyers, procurement needs to make informed, strategic purchasing decisions that impact your bottom line. The 5 P's give you a structured way to evaluate every purchasing decision holistically.

In procurement, "Product" goes far beyond basic features. We're talking about total requirements analysis.

Let me give you a real example. When sourcing industrial equipment, you don't just look at the machine's specs. You need to consider:

Maintenance requirements and service availability

Compatibility with your existing systems

Expected lifespan and reliability data

Environmental compliance certifications

Training requirements for your team

The biggest mistake I see? Companies focus solely on the initial purchase price without considering what happens when the product breaks down in two years. Always think about the entire product lifecycle.

This is where most people get it wrong. Price isn't just the number on the invoice.

Let's break down what really matters:

Acquisition cost: The actual purchase price

Operating costs: Energy consumption, required consumables

Maintenance costs: Service contracts, replacement parts

Disposal costs: Environmental fees, recycling costs

Hidden costs: Training time, installation downtime

Here's a simple rule: if you're not calculating Total Cost of Ownership (TCO), you're not really understanding your costs.

"Place" in procurement means optimizing your supply chain geography. It's about balancing cost against risk.

Consider these questions:

How many time zones away is your supplier?

What's the political stability of their region?

Are there single points of failure in your logistics chain?

What's your inventory carrying cost vs. shipping cost trade-off?

During the pandemic, companies that had diversified their "Place" strategy survived supply chain disruptions much better than those relying on single sourcing regions.

This is the P that makes procurement unique. Your processes determine your efficiency and compliance.

A strong procurement process includes:

Standardized supplier qualification

Clear approval workflows

Automated purchase order systems

Regular performance reviews

Continuous improvement mechanisms

I've seen companies save hundreds of hours monthly just by streamlining their requisition-to-order process. The right process isn't about bureaucracy—it's about removing friction.

People aren't just your internal team. This P covers everyone in your supply ecosystem.

You need to consider:

Supplier relationships: Are you building partnerships or just transactions?

Internal stakeholders: Are you aligning with their real needs?

Team capability: Does your team have the right skills for modern procurement?

Management support: Do executives understand procurement's strategic value?

Remember: the best strategy fails without the right people executing it.

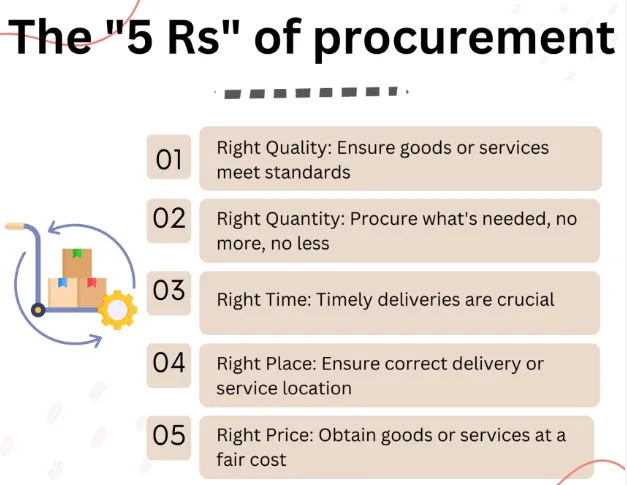

You might be wondering how this differs from the "5 Rights" of procurement (right quality, quantity, price, time, place). Here's the simple distinction:

The 5 Rights are your outcome measures—they tell you whether you made a good decision.

The 5 P's are your decision framework—they help you make that good decision in the first place.

Use the 5 Rights to evaluate performance, and the 5 P's to guide your strategy.

When helping a client source aluminum components, we applied the 5 P's like this:

Product: Specified not just alloy composition but also surface finish requirements and certification standards

Price: Calculated TCO including machining waste percentage and recycling value

Place: Chose a regional supplier despite higher unit price because logistics costs were 40% lower

Process: Implemented just-in-time delivery with automated inventory triggers

People: Included supplier's technical team in design improvements that reduced material waste

The result? 15% lower total costs and 99.8% on-time delivery.

Today's procurement requires updating our thinking:

Digital Product: Now includes data security features and API compatibility

Dynamic Pricing: Real-time market pricing and contract automation

Virtual Place: Cloud-based suppliers and digital service delivery

Automated Process: AI-powered analytics and blockchain for verification

Networked People: Remote collaboration and global team management

Plus, we now integrate ESG considerations into each P—from sustainable materials to ethical labor practices.

Knowing the theory is one thing; applying it is another. That's why we've created a practical toolkit you can use immediately.

[Download Your Free 5 P's Procurement Toolkit]

It includes:

5 P's Decision Checklist - Never miss a critical factor again

TCO Calculator Template - Automate your total cost calculations

Supplier Evaluation Scorecard - Compare vendors objectively

Implementation Roadmap - Step-by-step guide to roll this out

Start small. Pick one category of spend and apply the 5 P's framework to your next sourcing decision. You'll be surprised how much clearer your options become.

Remember, the goal isn't perfection—it's progress. Each time you use this framework, you'll make better decisions and build more value for your organization.

Ready to transform your procurement approach? Download your free toolkit above, or if you'd like personalized guidance, [schedule a quick consultation with our procurement experts]. We'll help you apply these principles to your specific challenges.

1. Q: How do we adapt the 5 P's framework for purchasing services instead of physical goods?

A: The principles are the same, but your focus shifts. For "Product," define the scope of work and deliverables clearly. For "Price," focus on value-based pricing or retainer models rather than unit cost. "Place" becomes about the service provider's location and their ability to deliver remotely or on-site. "Process" involves managing service-level agreements (SLAs), and "People" is absolutely critical—you're buying their expertise and the quality of their team.

2. Q: Our company is small and doesn't have a dedicated procurement team. Is this framework too complex for us?

A: Not at all. In fact, it's more valuable because it provides structure you might lack. Start by applying it to your biggest or most complex purchases first. You don't need fancy software; a simple spreadsheet where you jot down considerations for each of the 5 P's will dramatically improve your decision-making and prevent costly oversights.

3. Q: What's the single most common mistake companies make when first using the 5 P's?

A: They treat the P's as a checklist rather than an interconnected system. The biggest mistake is focusing too heavily on "Price" in isolation. For example, a cheaper "Product" might wreck your "Process" with constant breakdowns and require more "People" hours to manage. Always analyze how a decision in one P impacts the other four.

4. Q: How do we handle a situation where our internal stakeholders strongly prefer a supplier that scores poorly on the 5 P's evaluation?

A: Use the framework to depersonalize the conversation. Don't just say "I don't like that supplier." Instead, present the data. Show them, based on the 5 P's scorecard, where the preferred supplier has weaknesses (e.g., higher TCO, riskier "Place," weaker "Processes") and collaboratively discuss if those risks are acceptable. It turns a subjective argument into an objective business discussion.

5. Q: Can we use the 5 P's to evaluate our existing suppliers, not just new ones?

A: Absolutely, and you should! Conduct an annual or biannual 5 P's review with key incumbent suppliers. It helps identify areas for improvement in the relationship. Maybe their "Product" is still good, but their "Process" for invoicing is causing your accounting team grief. This review becomes the basis for a constructive strategic business review.

6. Q: How long does it typically take to see a tangible ROI after implementing this framework?

A: You can see immediate benefits on the very first sourcing project you apply it to, by avoiding a bad decision. For a broader, measurable financial ROI (like reduced costs or fewer supplier-caused disruptions), most organizations see a clear impact within 6 to 12 months as the framework becomes embedded in your culture.

7. Q: What if a supplier is excellent in 4 P's but weak in one? Should we automatically disqualify them?

A: Rarely. The goal is balanced decision-making, not perfection. The key is to understand the context of the weakness. If a supplier is weak in "Place" (e.g., they're far away), can you mitigate that with better inventory "Process"? If they're weak in "People," is it a training issue you can help with? Use the framework to identify risks, not just to eliminate suppliers.

8. Q: How does this framework integrate with our existing ERP or procurement software?

A: Think of the 5 P's as the strategic layer that guides how you use your tools. Your software manages the data; the framework helps you interpret it. You can create custom fields in your supplier profiles to capture 5 P's scores or use the categories to structure your RFQ documents and evaluation criteria within the system.

9. Q: Who from our company should be involved in scoring the "People" P?

A: Don't let procurement score this alone. "People" should be evaluated by everyone who interacts with them. This includes the technical team that vets their expertise, the account manager who handles the relationship, and the finance team that deals with their invoicing contacts. A 360-degree view is essential.

10. Q: We have a tight deadline. Is it okay to skip some of the 5 P's analysis to move faster?

A: A rushed process often leads to costly rework. Instead of skipping, do a "light" version. Spend 30 minutes on a rapid, high-level assessment of all 5 P's. This is often enough to surface major red flags. It's better to do a quick review of all five than a deep dive on just one or two. The framework's power is in the connections between the P's.

Contact us

Call Us: +86 193 7668 8822

Email:[email protected]

Add: Building B, No.2, He Er Er Road, Dawangshan Community, Shajing Street, Bao'an District, Shenzhen, China